Thermal Shock Test Chamber

As the Thermal Shock Test Chamber is a device that moves specimen to high and low temperatures room respectively during in a short time, to check for any abnormalities due to rapid temperature changes.

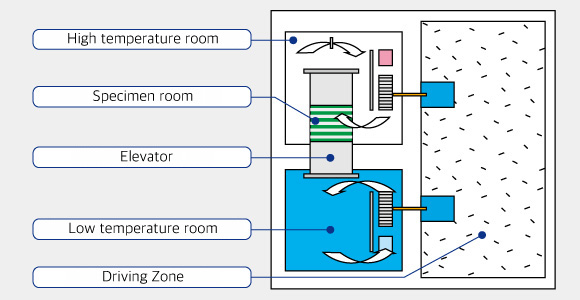

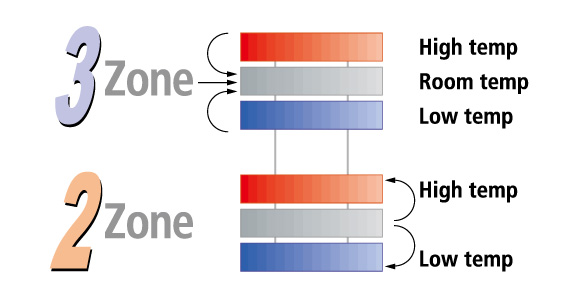

2 Zone Elevator Type (Specimen Movement Type)

3 Zone Damper Type (Air Circulation Type : High Temp.↔ Normal Temp.↔ Low Temp.)

Test the specimen for damage due to rapid temperature change!

Features

1. LCD Touch Screen method can be used easily by anyone with Korean and English interactive screen composition and operation method. The specimen(Test Basket) moves vertically up and down.

2. It is designed to disconnect power when any part of the safety device is operated during operation, and a part-by-part display (lamp light) is attached to the main control panel to facilitate identification of the operated safety device.

- - Low levels of noise and rapid cooling speed

- - Vertical motion of BASKET with separated temperature zones

- - Shortened temperature recovery time and rise time.

- - There is very little vibration and impact

3. Providing reliable test results

Uniform temperature distribution inside the chamber minimizes error of test results for many test subjects, thereby improving reliability of parts / products.

4. Extensive temperature control

As applying low-temperature, low-humidity control technology, It provides a wider temperature-humidity control area than any other product.

5. Providing an optimized environment for various standardized testing

Temperature Control Principle

Controller

-

Safe, Convenient Parameter Configuration

Detalled parameter mode allows user convenlence and data stability simultaneously

-

Wide, Clear Screen

800*480 high resolution 7°TFT LCD screen with 5,7° cutting size of previous products

-

Various Equipment Features

- DI & DO 16-point relay output (default) (A Contact: 10, C Contact 6)

- With additional relay board,Max DI & DO 32-point

-

Smart Output

- Simultaneous SSR & SCR output

- Independent supplementary output within program segment (0-100%)

- Overcoming limits of previous products, Max & SSR multi-drop(with 20㎃)

-

Various Program Configuration

500 pattern / 50,000 segment per channel

(Max. 100 segment per pattern) features various programs

-

Convenient Communication

- RS232C & RS485 communication ad standard

- Connect up to 31 units with Max. 38,400bps speed

- Ethemet communication available (option)

-

Systematic, Safe Data Management

- 100MB internal memary allows saving saving up to 25 days (with sampling speed 2 sec)

- FIFO(First In First Out) function ensures data safety

- Automatic simultaneous saving with interrnal and extemal memory

-

Variety of Storage Devices

- SD card & UsB support without options

- SD card provided

- Safe, convenitent transfer of parameter configuration via extern storage device

Specification(2 ZoneType)-1

← Scroll Left/Right →

| MODEL |

VT-TSC100 |

VT-TSC100-1 |

VT-TSC200 |

VT-TSC200-1 |

| Chamber System |

Two Zone Elevator System (2 ZONE) |

| Temp.Range (Max.) |

Heating Chamber |

RT ~120℃ |

RT ~180℃ |

| Cooling Chamber |

-40℃ ~ 0℃ |

-70℃ ~ 0℃ |

| Heating-Up Time |

RT ~ 120℃/30min |

RT ~ 150℃/40min |

| Pull-Down Time |

RT ~ -40℃/50min |

RT ~ -70℃/60min |

| Temperature Up Down Test. |

-40℃ ~ 100℃/within 5 min |

-55℃ ~ +150℃ within / 5 min |

Test Chamber Dimension

( W x D x H)mm |

300 x 300 x 300 |

500 x 500 x 500 |

300 x 300 x 300 |

500 x 500 x 500 |

| Power Consumption |

15Kw |

20Kw |

21Kw |

30Kw |

| Power Source |

AC 220V or 380V, 3Ø, 50/60 Hz |

| Air |

5~7Kgf/㎠ |

| Air in Size |

8Ø ~ 12Ø |

| Performance Guaranteed Ambient Temp. |

5℃ ~ 25℃ |

| Freezing system |

Mechanical compression two-way refrigeration system |

| Cooling system |

Air cooled System |

| Material |

In |

SUS 304 1.2t Steel Pate |

| Out |

SS41 Steel Plate Painting (1.6t) |

| Sensor |

T type |

* External appearance & type and specifiation may be to change without advance notice to enhance the performance of equipment

Specification(2 ZoneType)-2

← Scroll Left/Right →

| MODEL |

VT-TSC100 |

VT-TSC100-1 |

VT-TSC200 |

VT-TSC200-1 |

| Ampare Meter |

Digital Display 100/5A |

| Program Controller |

Program Touch Screen Type |

| (Option)RS-485/232 Communication Available |

| Insulation |

Ceramic wool & Glass wool (Depending on the temperature of use ordered, the thickness varies.) |

| Door |

Size |

900 x 900, Over lap signal open x 2set |

| Door packing |

Silicon Rubber Double packing (High temperature for use) |

| Blower Fan |

Aluminum Sirocco Fan |

| Viewing Window |

Vacuum Tempered Glass |

| Interior Sample Rack |

( SUS 304 ) Variable Type (2~3) Stage |

| S/W Mode |

Power S/W, High/Low S/W, Alarm S/W |

| Foot Master |

(F-100)Movable Wheel Attachment |

| Safety Devices |

- 1. ELB (Earth Leakage Breaker)

- 2. OHP (Over Heating Protective Device)

- 3. RPR (Reverse Phase Relay)

- 4. ROLP (Refrigerator Over Load Protector)

- 5. FMOLP (Fan Motor Over Load Protector)

- 6. HLPS (High/Low Pressure S/W)

- 7. CMOI (Circulation Motor Over Load Interrupter)

- 8. NFB (NoFuse Breaker)

|

Specialties

(Select Option) |

- 1. Cooling System → Water-cooled Type

- 2. Special dimensions can be ordered separately by the customer. (Test Chamber Size)

- 3. External materials may be selected separately by the customer.

|

* External appearance & type and specifiation may be to change without advance notice to enhance the performance of equipment.

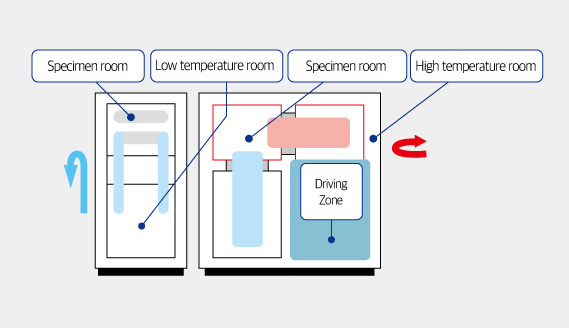

3 Zone Damper Type

The specimen is fixed and the specimen is tested using an air circulation method.

Specification (3 ZoneType)-1

← Scroll Left/Right →

| MODEL |

VT-TSC100 |

VT-TSC100-1 |

VT-TSC200 |

VT-TSC200-1 |

| Chamber System |

Three Zone Damper System (3 ZONE) |

| Temp.Range (Max.) |

Heating Chamber |

RT ~ 120℃ |

RT ~ 180℃ |

| Cooling Chamber |

-40℃ ~ 0℃ |

-70℃ ~ 0℃ |

| Heating-Up Time |

RT ~ 120℃/30min |

RT ~ 150℃/40min |

| Pull-Down Time |

RT ~ -40℃/50min |

RT ~ -70℃/60min |

| Temperature Up Down Test. |

-40℃ ~ 100℃/within 5 min |

-55℃ ~ +125℃ / 5min |

| Test Chamber Dimension (WxDxH)mm |

300 x 300 x 300 |

500 x 500 x 500 |

300 x 300 x 300 |

500 x 500 x 500 |

| Power Consumption |

20Kw |

25Kw |

30Kw |

40Kw |

| Power Source |

AC 220V or 380V, 3Ø, 50/60 Hz |

| Air |

5~7Kgf/㎠ |

| Air in Size |

8Ø ~12Ø |

| Performance Guaranteed Ambient Temp. |

5℃ ~ 25℃ |

| Freezing system |

Mechanical compression two-way refrigeration system |

| Cooling system |

Air cooled System |

| Material |

In |

SUS 304 1.2t Steel Pate |

| Out |

SS41 Steel Plate Painting (1.6t) |

| Sensor |

T type |

* External appearance & type and specifiation may be to change without advance notice to enhance the performance of equipment

Specification(3 ZoneType)-2

← Scroll Left/Right →

| MODEL |

VT-TSC100 |

VT-TSC100-1 |

VT-TSC200 |

VT-TSC200-1 |

| Ampare Meter |

Digital Display 100/5A |

| Program Controller |

Program Touch Screen Type |

| (Option)RS-485/232 Communication Available |

| Insulation |

Ceramic wool & Glass wool (Depending on the temperature of use ordered, the thickness varies.) |

| Door |

Size |

900 x 900, Over lap signal open x 2set |

| Door packing |

Silicon Rubber Double packing (High temperature for use) |

| Blower Fan |

Aluminum Sirocco Fan |

| Viewing Window |

Vacuum Tempered Glass |

| Interior Sample Rack |

( SUS 304 ) Variable Type (2~3) Stage |

| S/W Mode |

Power S/W, High/Low S/W, Alarm S/W |

| Foot Master |

(F-100)Movable Wheel Attachment |

| Safety Devices |

- 1. ELB (Earth Leakage Breaker)

- 2. OHP (Over Heating Protective Device)

- 3. RPR (Reverse Phase Relay)

- 4. ROLP (Refrigerator Over Load Protector)

- 5. FMOLP (Fan Motor Over Load Protector)

- 6. HLPS (High/Low Pressure S/W)

- 7. CMOI (Circulation Motor Over Load Interrupter)

- 8. NFB (NoFuse Breaker)

|

| Specialties (Select Option) |

- 1. Cooling System → Water-cooled Type

- 2. Special dimensions can be ordered separately by the customer. (Test Chamber Size)

- 3. External materials may be selected separately by the customer.

|

* External appearance & type and specifiation may be to change without advance notice to enhance the performance of equipment.