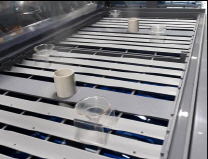

| Chamber | Specimen Tray and Components. |  |

|

||

|---|---|---|---|---|---|

After removing the support, spray tower |

Spray Scene |

||||

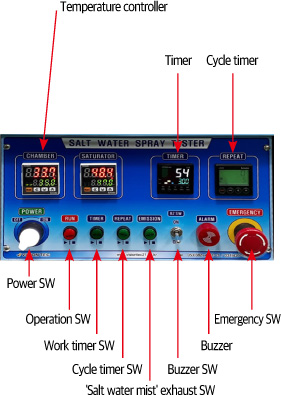

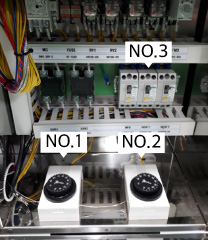

| Control Panel |  |

|

|||

| Pressure Gauge, Regulator Thermometers, Timers and Various S/W. |  |

||||

| Pressure | Pressure Gauge |  |

|

||

| Regulator |  |

|

|||

| Chamber | Over Heat Protector & Earth Leakage Breaker (OHP. ELB) |  |

|

||

|---|---|---|---|---|---|

|

|||||

| Nozzle Inspection Window |  |

|

|||

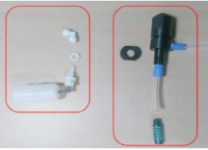

| Spray Nozzle |  |

|

|||

| Spray Nozzle components |  |

||||

| Salt Water Tank |  |

|

|||

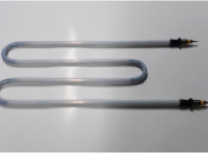

| Chamber Heater |  |

|

|||

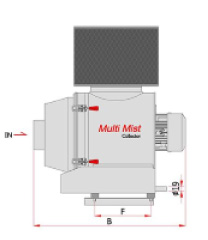

| Chamber Optional Spec. |

Dust Collector |  |

|

|---|---|---|---|

| Section View and Specification. |  |

|

|

| Touch Screen (Optional Spec.) |  |

|

|

| Chamber General Spec. |

Temperature Sensor |  |

|

| Chamber | Ion water manufacture device After producing 3000ℓ of ionic water, supplement the inner resin |

|

|

| Control Valve |  |

|

| Chamber | Saturator |  |

|

|

|---|---|---|---|---|

|

|

|||

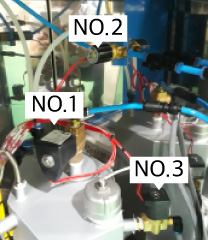

| Solenoid Valve → Appearance of attached solenoid valve |

|

|

||

| Solenoid Valve |  |

|

||

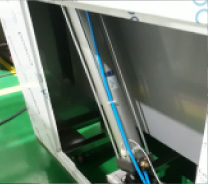

| Chamber Door | Automatic Opening / Closing Door |  |

|

|

| For Automatic Opening / Closing Doors Air Cylinder |  |

|

||

| MODEL | VT-ST100 | VT-ST200 | VT-ST300-66 | |

|---|---|---|---|---|

| Temperature Range | RT ~35℃ (* RT ~ 60℃ → Can be changed by customer order = Select Option) | |||

| Tester Method | Neutral Spray Test | |||

| Tester Temperature | Neutral (35℃±2℃) / CASS (50℃±2℃) Option | |||

| Temperature Control | Digital P.I.D. Control | |||

| Spray Volume | 1.5±0.5㎖ / 80㎠/h / Mean Value of 24 Hours Operation | |||

| Material | In | PVC 5t | PVC 5t | PVC 5t |

| Out | SUS 304 | SUS 304 | SUS 304 | |

| Door | PVC / Transparent | |||

| Dimension | In (WxDxH) | 600 x 450 x 450mm | 900 x 600 x 600mm | 1200 x 600 x 600mm |

| Out (WxDxH) | 1350 x 680 x 1250mm | 1650 x 850 x 1250mm | 1900 x 900 x 1280mm | |

| Heater Capacity | Chamber:0.35Kw Saturation Tank:0.5Kw |

Chamber:0.7Kw Saturation Tank:0.5Kw |

Chamber:0.9Kw Saturation Tank:0.5Kw |

|

| Safety Device | ELB.OHP | ELB.OHP | ELB.OHP | |

| Power Source | AC220V 1Ø / 50 / 60 Hz | |||

| Air Cylinder for Door Open | Option | Option | Option | |

| CASS | Option | Option | Option | |

| Touch Screen | Option | Option | Option | |

| MODEL | VT-ST300-86 | VT-ST400-86 | VT-ST500-86 | |

|---|---|---|---|---|

| Temperature Range | RT ~ 35℃ (*RT ~ 60℃ → Can be changed by customer order=Select Option) | |||

| Tester Method | Neutral Spray Test | |||

| Tester Temperature | Neutral(35℃±2℃)/CASS (50℃±2℃) Option | |||

| Temperature Control | Digital P.I.D. Control | |||

| Spray Volume | 1.5±0.5㎖/80㎠/h / Mean Value of 24 Hours Operation | |||

| Material | In | PVC 8t | PVC 8t | PVC 8t |

| Out | SUS 304 | SUS 304 | SUS 304 | |

| Door | PVC Transparent | |||

| Dimension | In (WxDxH) | 1200 x 800 x 600mm | 1500 x 800 x 600mm | 2000 x 800 x 600mm |

| out (WxDxH) | 2150 x 1100 x 1600mm | 2400 x 1100 x 1600mm | 2900 x 1100 x 1600mm | |

| Heater Capacity | Chamber:1.0Kw Saturation Tank:0.5Kw |

Chamber:1.4Kw Saturation Tank:0.5Kw |

Chamber:1.0Kw(2ea), Saturation Tank:0.5Kw |

|

| Safety Device | ELB.OHP | ELB.OHP | ELB.OHP | |

| Power Source | AC220V 1Ø / 50 / 60 Hz | |||

| Air Cylinder for Door Open | Free(Basis) | Free(Basis) | Free(Basis) | |

| CASS | Option | Option | Option | |

| Touch Screen | Option | Option | Option | |